It happened again… life got a little crazy. I had such a great streak of weekly blog posts going, but with the weather starting to get nicer (much faster than it usually does in Michigan might I add) life has gotten busy once again. It’s been three weeks since my last post – let’s see if I can recap what has been going on!

On Saturday, April 20th my good S13 friend Loren made the trek from Wisconsin to pick up my last remaining SR20DET drivetrain, this one being from my hatch. Loren bought my full OEM aero setup from my S13 hatch when I parted it out the first time back in 2012 and owns a few S13s, so it was cool to see my engine swap go to him as well. He arrived right on time and got things loaded up quickly. It’s always nice when things go smoothly! With that, I officially no longer own an SR20DET… aside from the one floating out on the ocean right now anyway. Another good friend of mine known as LA came over that afternoon and hung out with the family for a while, so that was a lot of fun as well. He transported a few other leftover parts for our friend Mikey that have been waiting to somehow make their way to him for a while. It felt amazing to have so much garage and basement space back.

The first Friday I missed posting here on the blog was April 27th. As fate would have it, my wife Alicia and I ended up driving to Chicago late that night to pick up our new puppy, Farley. Farley is an 11 week old Finnish Lapphund or “Lappy.” Ever since our husky Tomei died back in 2019, my daughters (and eventually Alicia) have been begging for a puppy. Tomei was a bit of a handful, and we just were not ready to rush into owning another dog so quickly with three young kids at home. However, being the last holdout of the family, I finally caved and said we could get a dog. Farley came from a breeder in Tennessee, but his sister was being sold to a family near Chicago. He was able to hitch a ride with his sister, which was a huge help in helping us get him. There aren’t a ton of breeders around for this type of dog, so we were really fortunate to be able to find one. It was a super long night, and I drank more energy drinks than I should have, but we eventually made it home with the new pup.

While we were in the Chicago area, I took the opportunity to drop off some parts I am getting painted for the 180SX with Brent of B Street Garage. I ended up taking him two pairs of mirrors (East Bear and Ganador) as well as two different OEM front bumpers – one from my 240SX with the plate cutout and R33 GTR N1 ducts, and the other with only a plate cutout. I have had a spare kouki 180SX bumper in storage for years, so I decided to cut out the license plate area and have that painted as well should I ever change my mind. That will leave me with all three configurations – stock, plate cutout only, and plate cutout with R33 GTR ducts. Hopefully that ends my indecision once and for all. I made quick work of the plate cotout with a dremel the morning before we left for Chicago. It sounds like the parts should be ready to pick up in a few weeks. If I can have the car professionally detailed and possibly ceramic coated, my hope is this will be the only paint work that it needs. Fingers crossed that I get that lucky, but we’ll see what happens.

While I had my front bumper setup apart, I decided to replace the four brackets that are still available new for the heck of it. I was fortunate enough to purchase all of the brackets new back when I switched from Hot Road back to OEM aero in 2016, and they are still in solid shape. A number of the brackets are now discontinued, but some are still available. I will probably make a post while I have everything apart to show all of the brackets and where they go as I think that would be valuable information for some people.

The day after we got home with the puppy, my good friend Frankie of Faction Motorsports pulled up all the way from new Jersey to purchase my 240SX rolling chassis. It took us a bit to get the car loaded up, but things generally went smoothly all things considered. I met Frankie in person at Final Bout II many years ago and he is an awesome dude that is very passionate about S13s. I don’t think my car could really have gone to a better person! He took a ton of my leftover parts off of my hands, and even hauled my kouki 180SX seats to NJ for a gentleman named Kevin to purchase. I am super grateful to Frankie for all of the help! I would like to say seeing the chassis leave my driveway (again) was bittersweet, but it really wasn’t this time. I was pretty glad to get it out of my hair this time, LOL. Maybe I will look back and regret it one of these days, but I haven’t dwelled on it much at all since the car left.

Frankie was kind enough to bring me a few items from his shop Faction Motorsports, including 3 of the 4 kouki 180SX brackets I mentioned earlier, a brand new SR20 fan shroud setup, and another kouki 180SX front bumper. I decided it would still be good to have a spare in storage should I ever need it, and I couldn’t pass up the chance for free shipping. I hopefully will never need to use this bumper, but it’s good to know I have it should they ever be discontinued. I got the upper bumper retainer bracket from Z1 Motorsports to complete the collection of new brackets (just because it happened to be out of stock at Faction.)

I’ve been waiting before I purchase too many other parts for the 180SX as I am not quite sure how I am going to get it home to Michigan yet, but I did find one thing I couldn’t pass up that just arrived today. I picked up this super clean black Bride Ergo from Get JPN out in California. I haven’t seen a black bride reclining seat this clean in a long time, so I decided it was worth picking up. This brings my current collection of seats to four with the Maxis, Zieg, Zeta and Ergo (all black.) Far more seats than I need for one car, but we’ll see what happens. These things are getting so tricky to find that I would love to keep all of them around and swap them out as I see fit. I always say I will do that with parts and end up needing to sell them, but I am hoping I can truly make it happen this time around.

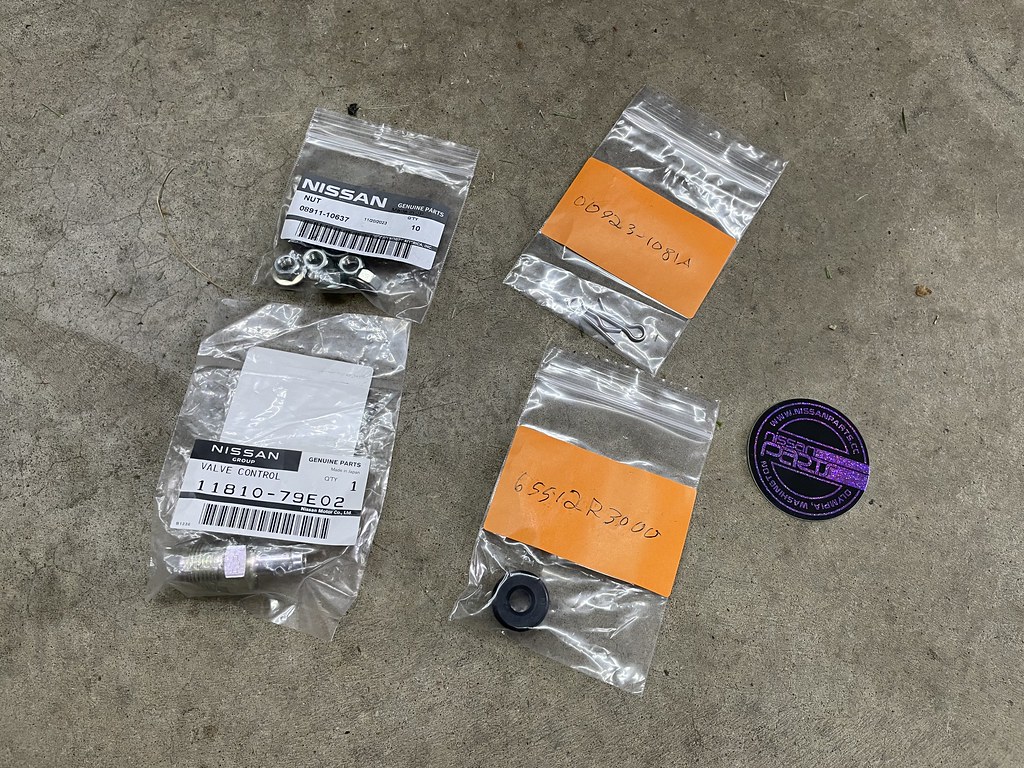

Finally, I had one small order from NissanParts.cc arrive that included the rubber bushing for the hood prop, six nuts for the wiper pivots, clevis pins for the clutch and brake pedal assemblies, and a new PCV valve for the car. More little odds and ends to add to the collection of restoration items.

Adding a puppy to the mix has definitely proven to make life a bit hectic. The girls have a lot going on with school wrapping up in a few weeks, and they have been spending a lot of nights out way past their bedtime playing with friends in the amazing weather we have been having. That being said, I feel like I haven’t had much free time at all to work on car stuff. However, I am still really excited for the car’s arrival and hope I have the time and energy to focus on it again soon. At least things are sort of at a lull right now anyway while I wait for its arrival.

180SX Shipping Update

Speaking of the status of the 180SX, the ship carrying the car arrived in Panama earlier this week. However, the ship it will be switching over to is currently in Brazil making its way to Panama. This resulted in a delay in the car’s ETA to Galveston, TX. The new ETA is June 1st, which throws a wrench into my plans for retrieving it – but at this point I just have to take things in stride and adapt to the situation as needed. As of right now, my target to go pick up the car is Father’s Day weekend. I am still debating if I should attempt to drive it home, or fork over the cash to get it shipped. I definitely don’t want to take on such a long journey alone, but I have some leads on a copilot. We’ll just have to wait a bit longer to determine the best strategy.

I received the import certificate for the car from Tweed a couple weeks ago and am currently in the process of adding classic car insurance to the 180SX as well. My 240s were never properly insured and that always stressed me out a fair amount, so I am excited to have this sorted out with the new machine. My hope is to have it fully registered and plated when I pick it up to Texas, but we’ll have to see how the process is going at that time. It’s a little tricky to understand what needs to be done and in what order, but I am navigating it OK so far thanks to help from people like Richard.

The previous owner of my 180SX shipped me a bunch of items from the car to avoid them potentially being stolen on the journey over. This package included paperwork and tools for the KTS coilovers he installed prior to the sale, plastic trims for the seat bolts, the ash tray, key ring trim, and the wiper arms.

The seller also shipped me the sunroof cover and the sunroof straps for the rear hatch area, which I am super excited about. One of the cars I parted out had these straps, but they were very dirty and rusty. It’s so cool to own a car in this original of a state. I was super worried about the sunroof cover arriving safely, but fortunately it didn’t get cracked like the one I imported for my 240 from Japan many years ago.

I’ve learned that my new car was loaded with a ton of cool options from the dealer. I want to wait to talk about a lot of them until I have the car in my possession, but two of them made their way here already – the optional kouki 180SX fog lights and window louvers. One of the fog lights is shattered unfortunately, and I am not quite sure why there are only two instead of four, but it’s still pretty cool to see. I don’t love the look anyway and will likely never us them, but it’s still a neat piece of the car’s history to have. The seller removed the window louvers and was selling them separately, but in an effort to preserve the car’s history and buy it in as original of a state as possible, I purchased them. Again, these are another part I have never been that interested in and likely won’t use, but I thought it was cool to have the louvers that were installed at the dealer when the car was new. They’re in great condition as well which is a plus!

That’s about it for the last three weeks! I need to decide soon if I am going to try to drive the car home or not. If I am, I need to send some maintenance parts to Houston and purchase a set of tires for the car so that it’s ready for the journey. Things should go from 0-100 pretty quickly over the next few weeks, but it’s definitely getting exciting.

Thanks as always for following along! Have a great weekend.